CableEye M4 Cable Tester Enhanced System 2, 152/2560 Testpoints, USB

Benefits of the Enhanced Cable Testing System CAMI CableEye M4 (CAMI-824)

- The enhanced cable tester with resistance (2-/4-wire) and capacitance measurement.

- Cable lenght, distance to break, Twisted-Pairing measurement.

- Supplies test documents with detailed test results for quality management.

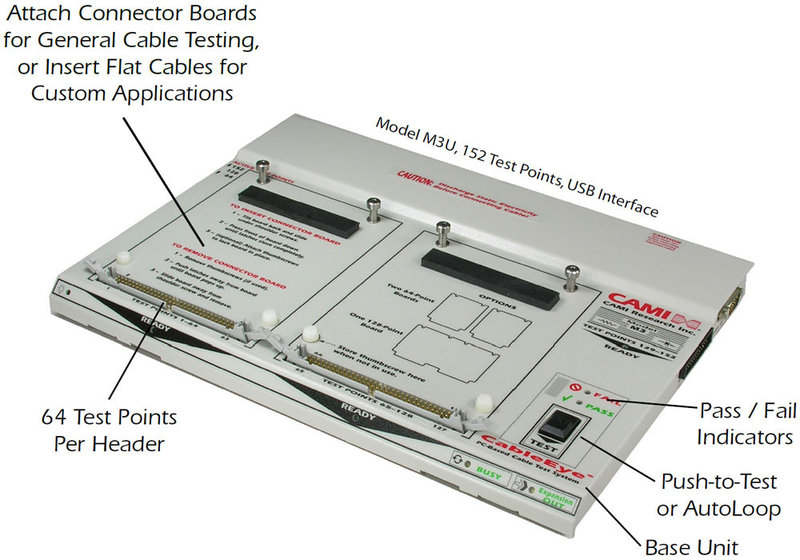

CAMI CableEye M4 Cable Tester Enhanced System 2: 152 Testpoints, Expandable to 2560, USB

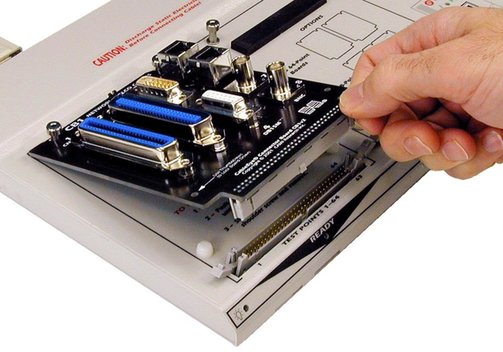

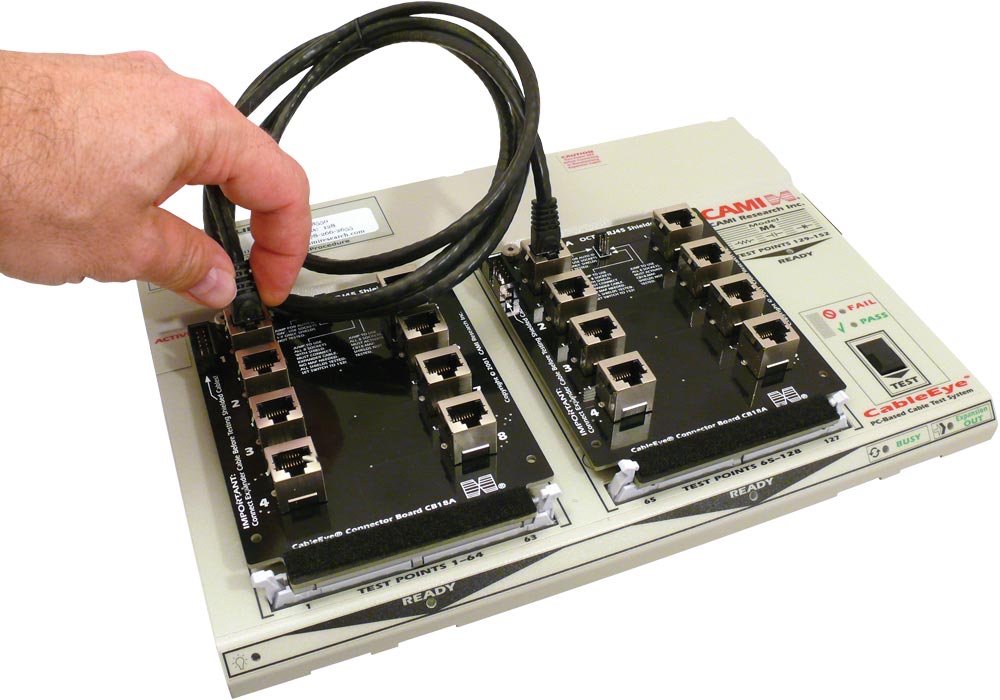

With the CableEye test system you can easily test any cable or cable harnesses with your PC, for example for continuity, open wires, short circuits or miswiring. The CableEye cable tester is particularly suitable for cable production, research and development, maintenance, network technology and prototyping as well as for everyday testing in industry, event technology etc. With different connector boards and a flexible software for Windows the system "learns" your cables and then tests them. Choose from a wide variety of plug-on connector boards to mate with most standard cables, and easily mount custom connectors for unusual applications.

- CableEye M4 (CAMI-824) - the enhanced system 2 for 152 test points, expandable to 2560.

- Store full cable documentation.

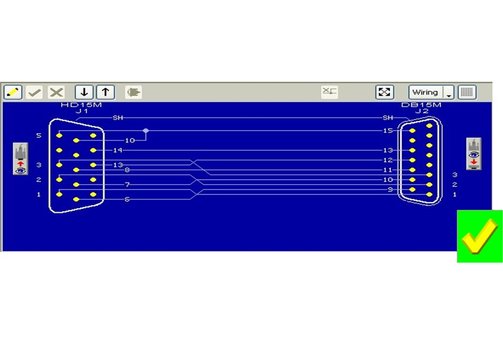

Print out cable wiring diagrams.

Print labels.

Log and print error protocols. - Visualize cable wiring: Automatically draw schematics from measured cable connections. Compare cables.

Easy testing of cable leads. - Plug-in connector boards, easy to install, for various connector types like BNC, RJ45, D-sub, ribbon cable/IDC and many more.

- Connects to the PC via USB.

- Easy-to-use Windows software. Can be set up for one-button operation to speed production testing. Unskilled operators need only to press the TEST pushbutton on the fixture to trigger an involved test sequence set up by the quality control engineer, with results automatically logged to disk for later analysis and report generation.

- Continuity test:

Detects open lines, short circuits and miswired cables.

Pass/fail test with a 'known good' sample.

Locate intermittent connections and identify their position in the cable. - Resistance measurement:

Testing of resistors integrated in the cable, e.g. termination, pullup/pulldown (depending on model).

Test of diode orientation. - Advanced measurement functions:

Resistance (4-wire Kelvin).

Capacitance.

Cable length, wire length.

Length to break.

Cable wisted pairing.

Model Overview

| Model | Low voltage - M4 - CAMI-824 |

| Control module test points | 128 + 24 accessory test points |

| Max. test points | 2560 |

| Test time (128 test points) - continuity only | 0.15 s |

| Test time (128 test points) - with resistance test | 0.40 s |

| Resistance thresholds | 0.02 Ω...6 MΩ |

| Resistance accuracy - 10...100Ω | ±0.15 Ω |

| Resistance accuracy - 100 Ω...1 MΩ | 1% |

| Resistance accuracy - full range | Lesser accuracy over full range |

| Resistance Range | 0.02 Ω...6 MΩ |

| 4-Wire Kelvin | 20 mΩ ±20 mΩ (20 mΩ...15 Ω, test current 3.3 mA) |

| Intermittent connection scan rate | 18 Scans/s - 128 test points, 47 Scans/s - 64 test points |

| Diode measurement | Orientation, forward voltage and reverse breakdown <10 V |

| Test voltage | Adjustable: 1.7/2.5/3.3/5/10 V |

| Max. test current | 3.3 mA |

| Capacitance range | 100 pF...100 mF |

| Capacitance accuracy | ±5% |

| Capacitance measurement rate | 20 Meas./s at 100 nF or less |

| Twisted pair measurement | Yes, 182.9 cm/6 ft min. length |

| Measurement cable length | Min. length 182.9 cm/6 ft, ±91.4 cm/3 ft |

| Measurement distance to break | Min. distance to break 182.9 cm/6 ft, ±91.4 cm/3 ft |

| Dwell time range | 1 µs...100 ms |

| Insulation resistance measurement | 6 MΩ at 10 V |

| Digital-I/Os | Pairs of test points used as inputs, 50+ relay outputs with optional relay boards (item 765) |

| Calibration | Recommended yearly |

| Test point connectors | 64-pin dual-row headers, 2.54 mm/0.1" centers; two per 128-point module |

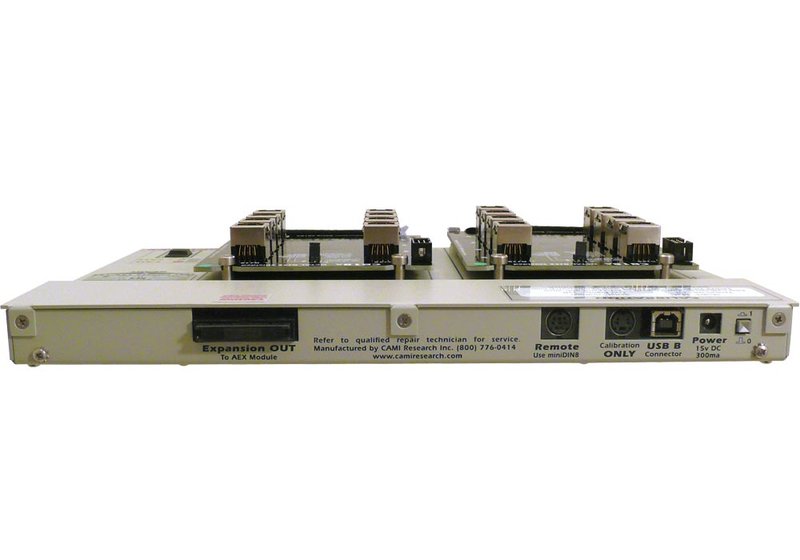

| Remote control socket | Yes, MiniDIN8 Connector for use with e.g. footswitch, external control panel |

| Probe socket | Yes; probe included with tester; accessory port also usable with minihook cables |

| Power requirement | 18 VDC/500 mA (max.)/9 W |

| Weight | 1.1 kg |

| Computer requirements | Any Windows-capable machine running Windows 7 or later; compatible with touchscreen and laptop PCs |

| USB interface | USB 1.1, fast |

| CableEye M4 - Measurement Functions | |

| Continuity | Opens, shorts, miswires |

| Intermittent faults | |

| Complex networks, backplanes | |

| Resistance | Connection, non-Connection quality |

| Resistance (2-wire) | |

| Continuous resistance scan | |

| Fixture resistance nulling | |

| Resistance (4-wire Kelvin) | |

| High current resistance | |

| Capacitance | Wire length, cable length |

| Length to break | |

| Twist pairing | |

| Insulation quality | Insulation resistance |

| In-Line Components | Resistors |

| Diodes - orientation | |

| Diodes - forward voltage | |

| LEDs - orientation | |

| LEDs - color detection | |

| Zener diodes - orientation | |

| Zener diodes - forward voltage | |

| Zener diodes - reverse breakdown voltage <10 V | |

| Capacitors | |

CableEye, All Models and Expansions

| Low Voltage Testing | |||

| ▸CAMI-814 | CableEye M2Z | Basic system/entry level | 128 test points, not expandable. USB interface |

| ▸CAMI-826 | CableEye M3Z | Enhanced system 1 | 152 test points, expandable to 2560. Can also measure resistance (0.1 Ω...5 MΩ) and diodes. USB interface |

| ▸CAMI-824 | CableEye M4 | Enhanced system 2 | 152 test points, expandable to 2560. Can also measure resistance (0.02 Ω...6 MΩ), diodes, capacitance, twisted-pairing. USB interface |

| Low Voltage Testing Expansion Modules | |||

| ▸CAMI-827 | M3Z-AEX | Expansion module for the M3Z system (826), stackable version. 128 additional test points. Use more modules to expand the CableEye systems up to 2560 test points). Connected to the base system via ribbon cables. | |

| ▸CAMI-825 | M4-AEX | Expansion module for the M4 system (824), stackable version. 128 additional test points. Use more modules to expand the CableEye systems up to 2560 test points). Connected to the base system via ribbon cables. | |

| High Voltage Testing | |||

| ▸CAMI-829 | CableEye HVX | HVX system | Applies voltage up to 1500 VDC/1000 VAC, measures resistance between 0.1 Ω and 1 GΩ, 128 test points, expandable to 1024 |

| ▸CAMI-829A | CableEye HVX-21 | Enhanced HVX system | Applies voltage up to 2100 VDC/1200 VAC, measures resistance between 0.1 Ω and 5 GΩ, 512+ test points |

| High Voltage Testing Expansion Modules | |||

| ▸CAMI-828 | HVX-AEX | Expansion module for HVX/CAMI-829: Adds 128 testpoints. | |

| ▸CAMI-828 | HVX-21-AEX | Expansion module for HVX-21/CAMI-829A: Adds 128 testpoints. | |

CableEye is a modular system. A variety of optionens and connector boards are available. The webshop only shows a selection. Contact us for individual configurations or special connector board designs. Find a CB board compatibility chart and other overviews ▸here.

Frequently Asked Questions:

Question: What are the CableEye components and what exactly do I need?

Answer: CableEye consists of a basic device, the actual tester. This is available in different versions and expansion levels, depending on the number of test points and the range of functions (M2U, M3Z, M4, HVX and extensions). In addition, there are so-called connector boards (CBs, usually in pairs), which are used to adapt your connectors/cables to the tester. For example, to adapt 26-, 34-, 40-, 50-, or 60-pin ribbon cable connectors, you need the CB2 model (CAMI-732). Many CBs are available unassembled or assembled for maximum flexibility. CBs for special connector types that are not yet available can be designed and added by the user or as an optional service. For cable harnesses, the system can be expanded up to 2560 test points. Our CableEye experts will be happy to advise you and help you configure your system.

Basically you should answer these questions to define the first rough scope of your tester:

- How many cores do the cables to be tested have (or how many pins do the connectors have)? Which connector types are used?

This determines the number of test points as well as the required connector board types. - What exactly has to be tested?

This determines the required basic device, as depending on the model, the basic devices have a different scope of functions, see web store. - Will I stick to exactly this test scope "forever" or do I want to test other, more complex cables in the longer term?

This is also decisive for the basic device, because not all models can be expanded to the same number of test points and test functions.

Question: What does "test points" mean for the CableEye system?

Answer: Each connection/contact is called a test point. Example: A cable with a 25-pin D-sub connector has 25 pins/test points on one side, plus the shield, and 25 test points and shield on the other side. A total of 52 test points are therefore required here. For more complex cables and harnesses, the number of test points can increase very quickly. CableEye basic systems with 128 or 152 test points as standard are available. With extensions, they can be expanded up to 1024 or 2560 test points.

Question: For which cables is the CableEye tester suitable?

Answer: The CableEye tester primarily tests for continuity or open circuit/line break, short circuits, miswires, resistors and inline components. So typical cable types as DUTs are power supply lines for low voltage (up to 48 V), audio, video and short data cables etc. Typical connector types, for which there are also ready-made adaptor boards for the CableEye system, are various D-sub, flat ribbon connectors, Cinch, XLR, USB, SCSI, various round connectors and many more. The CableEye system is also particularly suitable for cables with many cores and complex cable harnesses.

For testing with higher voltages (up to max. 2.1 kVDC or 1.2 kVAC), the CableEye HVX version is intended. Additional tests include dielectric strength and insulation resistance.

The CableEye system cannot be used to test fiber optic cables - OTDR devices are used here. Likewise, the CableEye system is not used for cables where frequency-dependent transmission properties, characteristic wave impedance, attenuation, etc. must be determined. These include, for example, cables for the transmission of high-frequency signals such as high-speed data cables, some control cables for robots, cables for satellite and radio transmissions, etc. VNAs (vector network analyzers) and TDRs (time domain reflectometers) are used here.

Question: Can I find a "loose contact" with the CableEye?

Answer: "Loose contacts", or more generally "intermittent faults", often occur in cables that are subjected to high mechanical stress due to movement or frequent connection/disconnection. But of course they can also be caused by production errors such as cold solder joints or bad crimps, among other things. Finding such faults is difficult, as they may only occur occasionally. To reliably detect intermittent faults, the CableEye system works with tests in a continuous loop. For example, the cable can be moved by the user during the continuous test to "trigger" the fault.

Question: I would like to have the cable test carried out by non-technically trained assistants, is that possible?

Answer: The CableEye system has an interface (USB) to the PC and can be automated with Macros. This allows you to prepare entire test sequences, including the output of test documents, to such an extent that even less trained personnel can operate the system after minimal instruction.

Information on product safety:

Manufacturer:

CAMI Research Inc., 42 Nagog Park, Suite 115m Acton, MA 01720-3301/USA

www.camiresearch.com

Responsible person:

Meilhaus Electronic GmbH, Am Sonnenlicht 2, 82239 Alling/DEU

info@meilhaus.com

Related Products

Customers also bought