Thermography - All Temperature Details in a Thermal Image

Temperature Measurement - With Thermal Contact or by Thermal Radiation

Temperature measurement plays an important role in everyday life as well as in research and development, in medicine and in industrial environments. Temperature is measured in two ways: by thermal contact or by non-contact measurement using thermal radiation.

Today, for measurement by thermal contact, temperature sensors of all kinds (thermocouples, RTDs, thermistors, semiconductor sensors, etc.) are mainly used - although there are other methods such as the classic gas/liquid thermometer.

When measuring using thermal radiation, pyrometers/point/IR thermometers are used on the one hand and imaging methods in IR/thermal imaging cameras on the other.

IR/spot thermometers do not work with imaging processes. Like a thermometer, they display the point temperature of a targeted location numerically. They therefore represent a single pixel of a thermal imaging camera, so to speak.

The thermal imaging camera (IR/infrared, thermal or thermographic camera) also receives thermal radiation (medium and long-wave infrared in the spectral range of approximately 3.5 to 14 µm). However, not only with a single point/pixel but with a complete pixel matrix with a certain resolution (for example 640 x 460 = 294,400). The thermal radiation emitted by surfaces is converted into visible light in the camera and reproduced as an image of the recorded objects (thermal image). The image is displayed in "false colors", whereby different palettes can usually be selected, for example dark/black/blue for less thermal radiation, red, orange, yellow and up to white for a lot of thermal radiation. Thermal imaging cameras can often overlay this thermal image with a photo-optical image from an integrated classic megapixel digital camera, so that additional "photographic" information and details are available.

Picture 1: Thermal image in false color representation (top image: FOTRIC, bottom image: comparison of visual and thermal image, HIKMICRO).

The applications are diverse and place different demands on the thermal imaging cameras:

Areas of Application for Thermography - Examples

- Building technology and construction industry (insulation/energy efficiency, HVAC systems/heating, ventilation, air conditioning, etc.).

- Security (fire departments, rescue services, people search, surveillance in general, especially transportation monitoring of electric vehicles/batteries).

- Environmental technology, renewable energies, agriculture, wildlife monitoring.

- Industrial maintenance, repair, inspection of machinery, equipment, electrical systems, energy supply, energy efficiency.

- Food industry.

- Human, sports and animal medicine.

- Research, development, automotive, aerospace, energy efficiency/heat loss of assemblies, non-destructive material testing.

The requirements for the thermal imaging camera result from these considerations, among others:

- Distance to the object - wide angle to macro.

- Size of the object - wide angle to macro.

- Importance of details or only rough, local classification.

- Required technical data such as sensitivity, resolution, field of view/FoV, focus, etc.

- Type of lenses, fixed or interchangeable.

- Supporting software for capturing, interpreting and analyzing in the camera or after transferring the images to the PC.

- PC interface(s) and/or interfaces to mobile/smart devices.

- Robustness and type of operation depending on the location.

- Are still images sufficient or are video sequences also desired.

- Design: "classic" with a handle, as a compact camera, or as an attachment for the smartphone; stationary or mobile/handheld with/without display.

- Price.

Thermography in Research and Development/R&D - for Example, Heat Development and Heat Loss on Assemblies

Picture 2: Thermal imaging cameras for R&D applications - versions from FOTRIC (left, center) and HIKMICRO (right).

The above considerations result in the following requirements for a thermal imaging camera:

- The objects are electronic assemblies such as circuit boards.

The distances to the object and the sizes of the objects are often relatively small. Details such as individual conductor tracks and soldering points are important. A high resolution as well as good macro lenses and possibly interchangeable lenses are required. - Mountability on a tripod is useful.

- A display and many sophisticated evaluation functions in the camera can be omitted in favor of a connection to the PC and left to the PC.

- Robustness important, but no extreme requirements such as for outdoor use, fire departments, etc.

Thermal imaging cameras for the R&D sector are available from the manufacturers ▸FOTRIC and ▸HIKMICRO:

General and Industrial Thermography

In this area, the requirements for the cameras differ fundamentally from those mentioned above:

- The objects are often sections of buildings, larger machines or plants.

The distances to the object and the areas of the objects are larger. Very fine details are often not absolutely necessary. It is sufficient to localize the fault as precisely as possible. Wide angles and interchangeable lenses depending on the situation are required. - The camera is preferably held in the hand and should therefore have a comfortable weight, be non-slip and have a good grip. Under certain circumstances, it must be possible to operate the camera with protective gloves.

- A display and many sophisticated measurement and evaluation functions directly in the camera facilitate work on site. An interface for transferring the data for later evaluation and documentation is often required. Depending on the application, it can be useful, for example, if the camera itself can form a WLAN server so that there is no need for a network.

- Robustness is important, for example in terms of temperature ranges, IP protection classes and drop tests.

"Classic" thermal imaging cameras, compact camera designs and modules for smartphones can be found here:

Other Imaging Methods - Acoustic Cameras

In addition to the thermal imaging camera, the "acoustic camera" has established itself as a further imaging method. It is used, for example, to detect gas and compressed air leaks and partial discharges in electrical systems (corona, floating, surface and particle discharges). Detection is with a matrix of low-noise MEMS microphones. The image shown is that of a megapixel digital camera in which the detected sound events are displayed. The acoustic part of the image is displayed with a number of selectable palettes, similar to a thermal image.

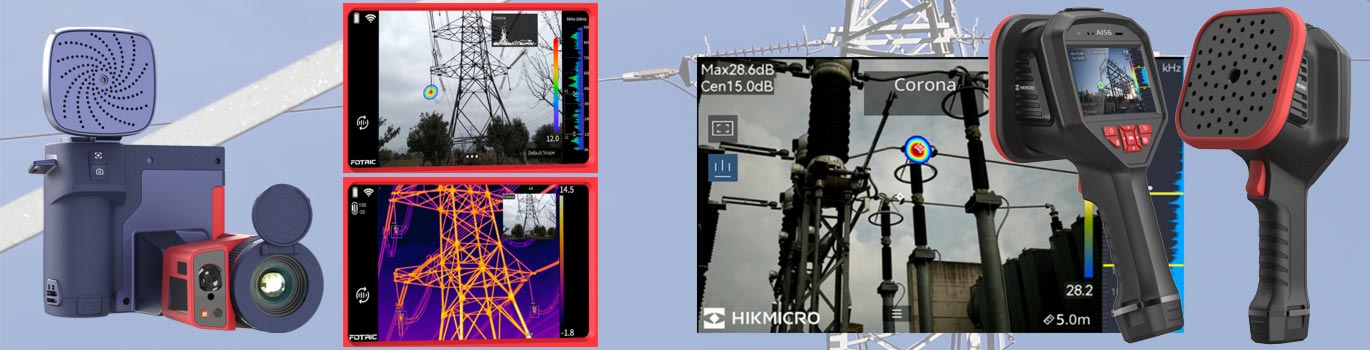

Picture 3: Different versions of acoustic cameras from FOTRIC (left, AcouTherm combined with thermal imaging function) and HIKMICRO (right).

The FORTIC acoustic camera "AcouTherm" combines megapixel, thermal imaging and acoustic cameras in one device - an innovative approach that enables the search for problem areas "with all senses".

Interested? Please contact us!

More Acoustic Cameras:

Couldn't find the desired product in the shop? Just ask us - more products available!

Get in Contact with the Meilhaus Electronic Team: